| Availability: | |

|---|---|

artificial synthetic leather Production line

Main machines:

Electronic Weighing Opening system bale opener: Suitable for opening and mixing of two or more fibers for pre-treatment system.

Mixing bale opener:

Open and mix one or multiple fibers and inputs them to the next process.

Big cabin blender:

Provides full mixing and storage for fibers after various initial openings to facilitate continuous production.

Vibrating feeding hopper:

Forms a uniform cotton layer from the mixed fibers and continuously sends them to the next process.

Carding Machine:

Suitable for carding fibers into a mesh.

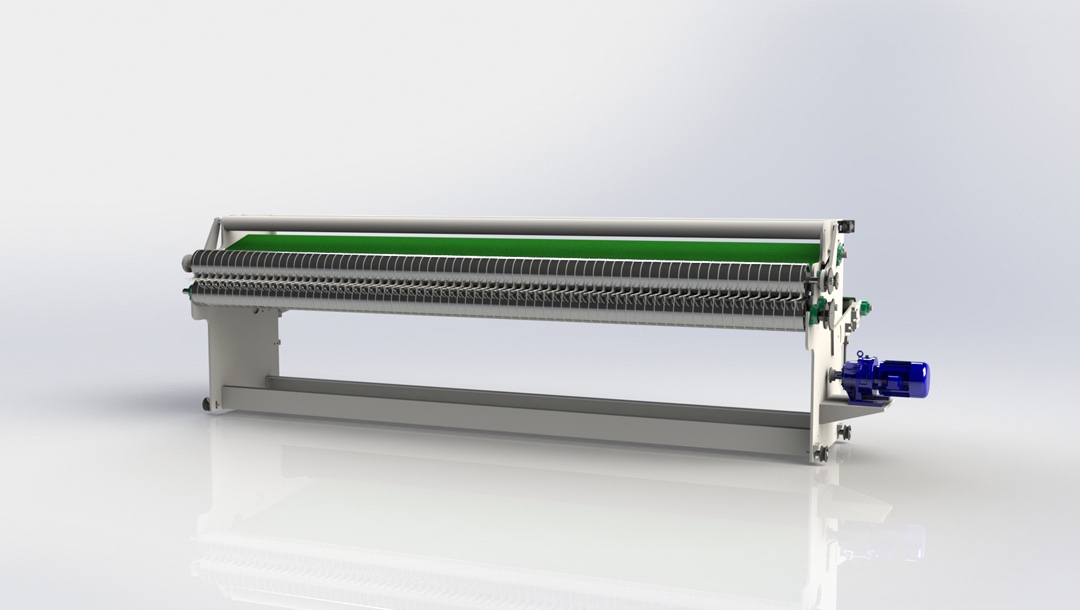

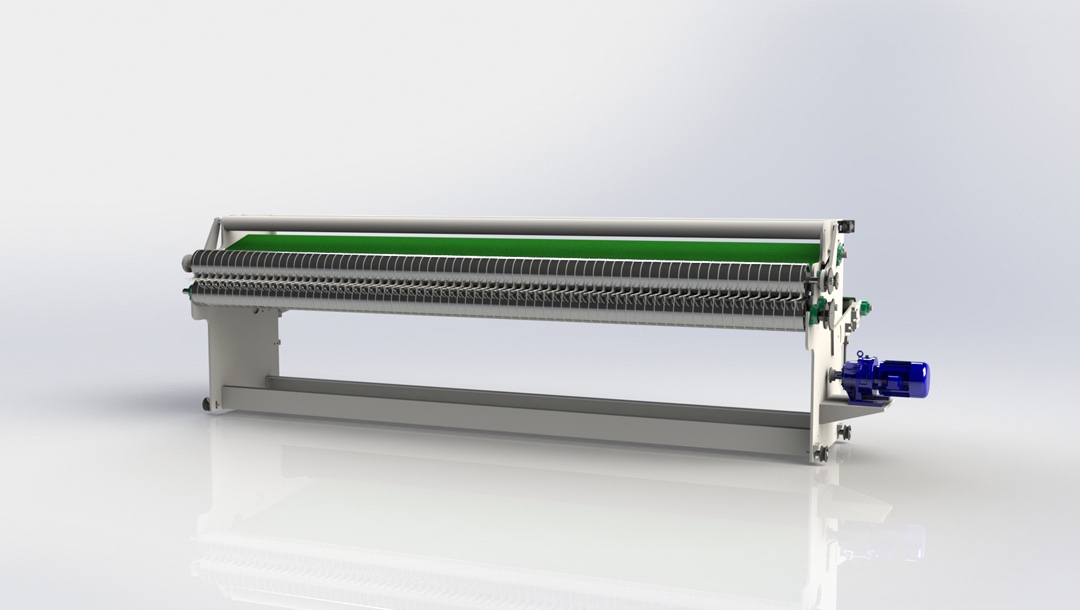

Cross lapper:

Lays the mesh uniformly and folds it crosswise to the desired width and thickness, then sends it to the next process.

Feeding apparatus:

Feeds the laid cotton mesh of different thicknesses uniformly into the pre-needling area.

Calender:

Suitable for surface treatment of non-woven fabrics to achieve the required surface finish and thickness.

Middle Speed Needle loom:

Pre-strengthens the fluffy and weak cotton mesh output by the carding machine.

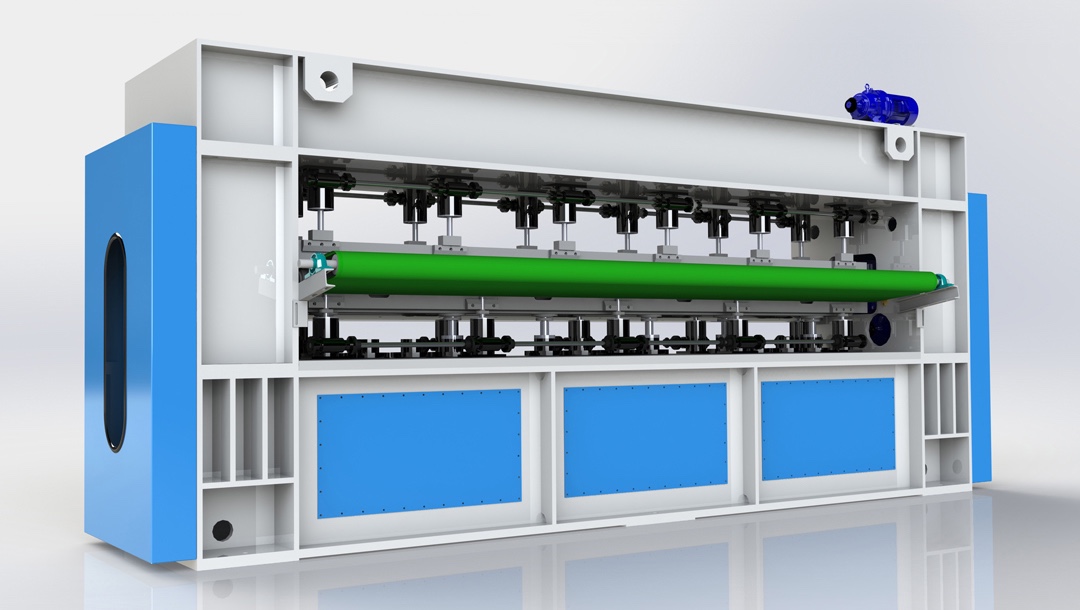

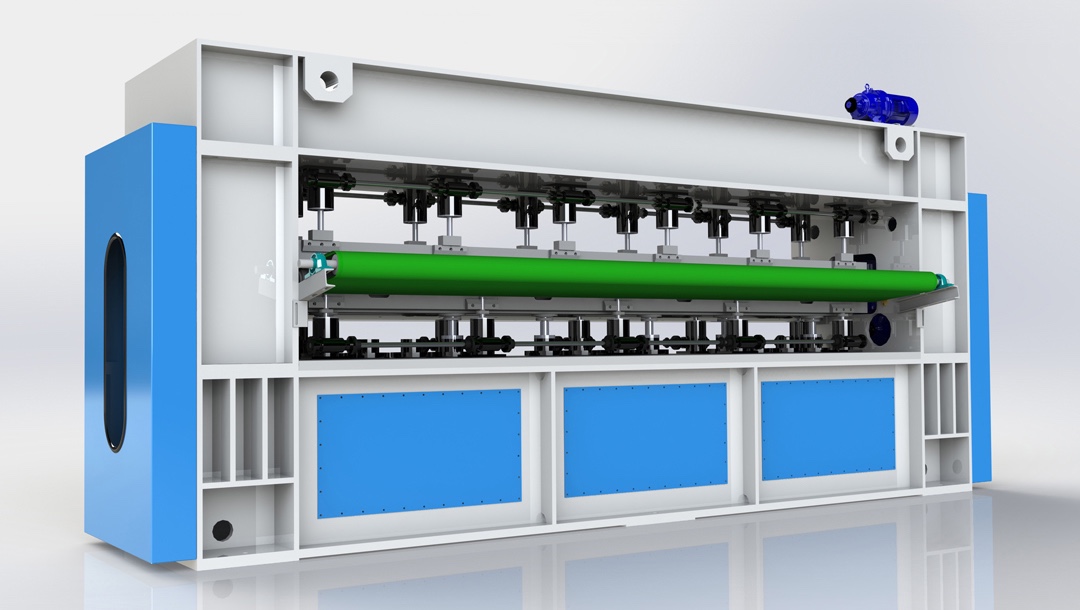

High Speed Needle loom:

The needle board drives the needle up and down at high frequency, and the hook on the needle drives the fibers to intertwine with each other, forming a dense non-woven fabric.

|  |

|  |

| |

artificial synthetic leather Production line

Main machines:

Electronic Weighing Opening system bale opener: Suitable for opening and mixing of two or more fibers for pre-treatment system.

Mixing bale opener:

Open and mix one or multiple fibers and inputs them to the next process.

Big cabin blender:

Provides full mixing and storage for fibers after various initial openings to facilitate continuous production.

Vibrating feeding hopper:

Forms a uniform cotton layer from the mixed fibers and continuously sends them to the next process.

Carding Machine:

Suitable for carding fibers into a mesh.

Cross lapper:

Lays the mesh uniformly and folds it crosswise to the desired width and thickness, then sends it to the next process.

Feeding apparatus:

Feeds the laid cotton mesh of different thicknesses uniformly into the pre-needling area.

Calender:

Suitable for surface treatment of non-woven fabrics to achieve the required surface finish and thickness.

Middle Speed Needle loom:

Pre-strengthens the fluffy and weak cotton mesh output by the carding machine.

High Speed Needle loom:

The needle board drives the needle up and down at high frequency, and the hook on the needle drives the fibers to intertwine with each other, forming a dense non-woven fabric.

|  |

|  |

| |