| Availability: | |

|---|---|

Main machines:

Electronic Weighing Opening system bale opener:

Suitable for opening and mixing of two or more fibers for pre-treatment system.

Fine opener:

Proportional raw materials are fed into the machine, where they are fully opened and mixed, and then sent to the next stage through a cotton-feeding fan with strong magnets for impurity removal.

Big cabin blender:

Provides full mixing and storage for fibers after various initial openings to facilitate continuous production.

Vibrating feeding hopper:

Forms a uniform cotton layer from the mixed fibers and continuously sends them to the next process.

Carding Machine:

Suitable for carding fibers into a mesh.

Cross lapper:

lays the mesh uniformly and folds it crosswise to the desired width and thickness, then sends it to the next process.

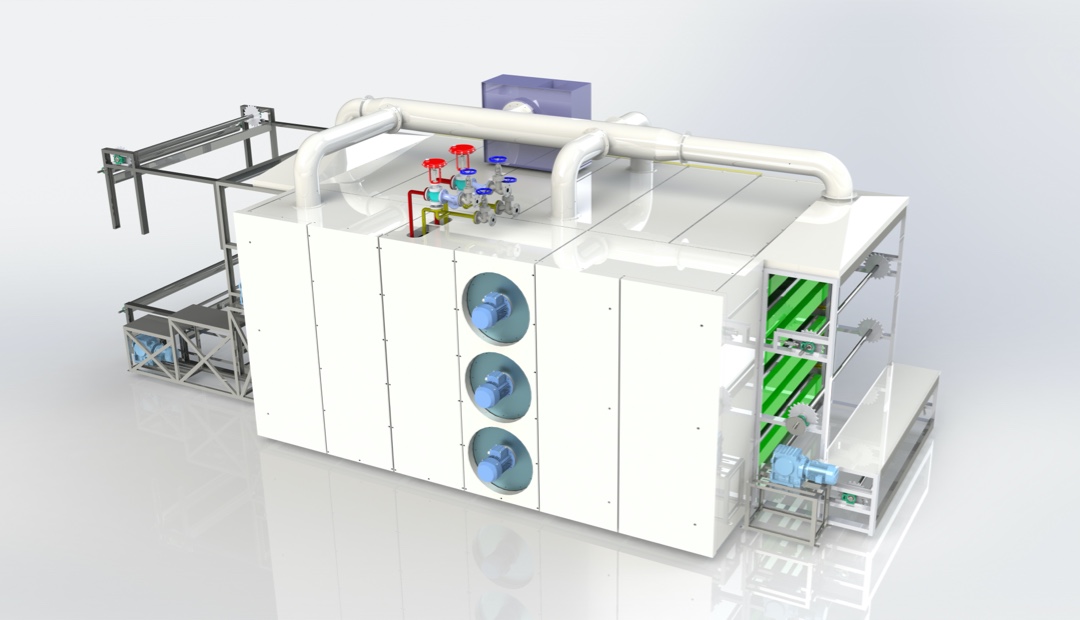

Spraying Cotton Drying Room:

Suitable for producing spray-coated cotton, non-coated cotton, imitation silk cotton, needle-sprayed cotton, etc.

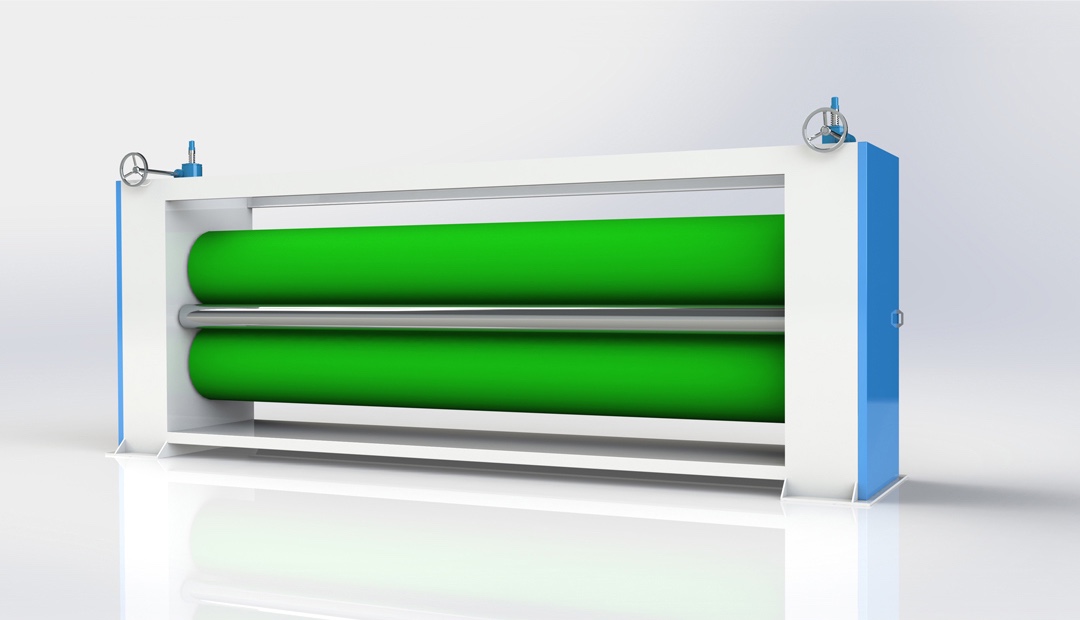

Calender:

Suitable for surface treatment of non-woven fabrics to achieve the required surface finish and thickness.

|  |  |

| ||

Main machines:

Electronic Weighing Opening system bale opener:

Suitable for opening and mixing of two or more fibers for pre-treatment system.

Fine opener:

Proportional raw materials are fed into the machine, where they are fully opened and mixed, and then sent to the next stage through a cotton-feeding fan with strong magnets for impurity removal.

Big cabin blender:

Provides full mixing and storage for fibers after various initial openings to facilitate continuous production.

Vibrating feeding hopper:

Forms a uniform cotton layer from the mixed fibers and continuously sends them to the next process.

Carding Machine:

Suitable for carding fibers into a mesh.

Cross lapper:

lays the mesh uniformly and folds it crosswise to the desired width and thickness, then sends it to the next process.

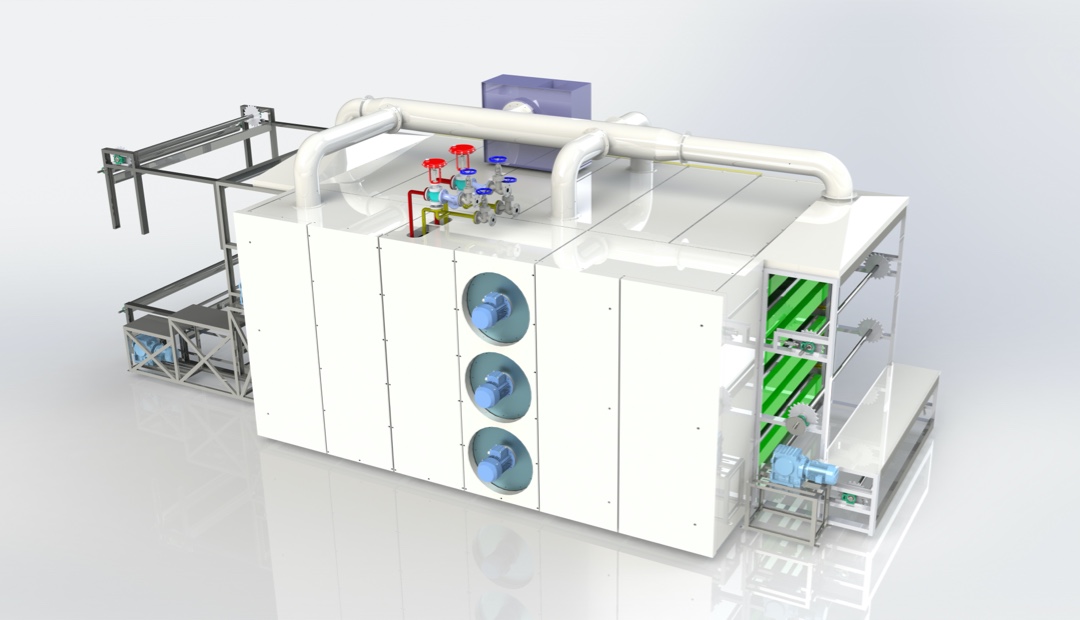

Spraying Cotton Drying Room:

Suitable for producing spray-coated cotton, non-coated cotton, imitation silk cotton, needle-sprayed cotton, etc.

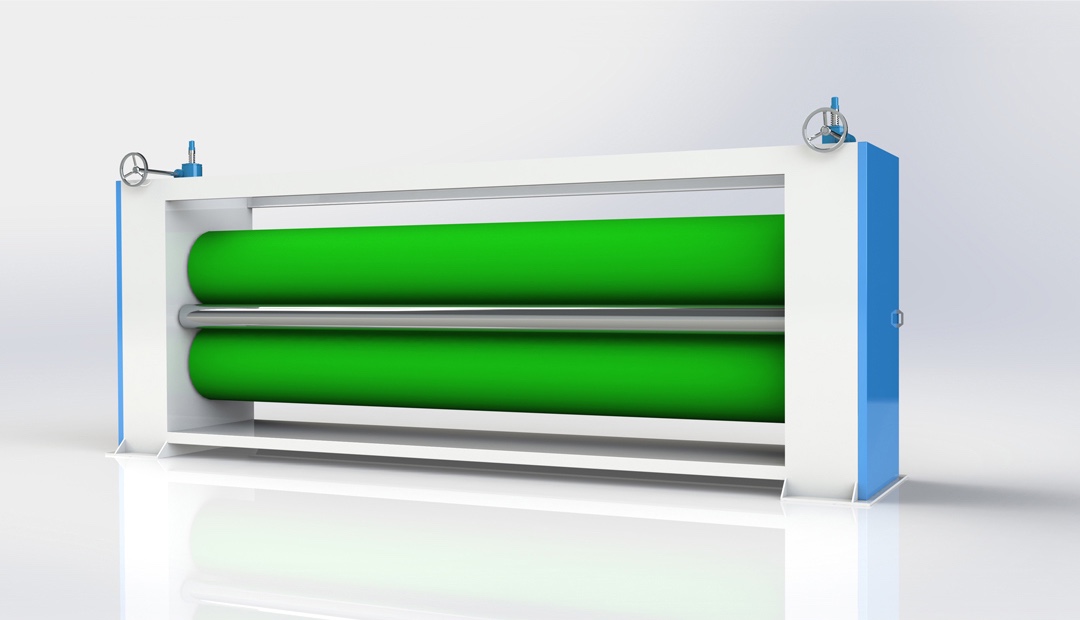

Calender:

Suitable for surface treatment of non-woven fabrics to achieve the required surface finish and thickness.

|  |  |

| ||