Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

The process of fabric production is intricate, with woven fabrics playing a crucial role in the textile industry. Weaving, the interlacing of warp and weft threads, has been the foundation of fabric creation for centuries. The efficiency and quality of woven fabrics are greatly influenced by the machines used.

In this article, we will explore the various machines that create woven fabrics, from traditional looms to modern automatic machines. By the end, you will understand the key factors in selecting the right woven fabrics machine for your needs.

A woven fabrics machine, commonly known as a loom, is a textile machine used to weave yarns into fabrics by interlacing them at right angles. The primary function of a woven fabrics machine is to hold the warp threads under tension while inserting the weft threads through them. The result is a fabric that is durable, stable, and ready for various uses, including clothing, upholstery, and industrial materials. Woven fabrics machines come in various forms, each designed to meet specific needs in fabric production.

Weaving machines have evolved significantly over the years. The primary distinction between these machines lies in the way they insert the weft thread into the warp threads. Traditional hand looms use manual labor to move the shuttle through the warp threads, while modern looms incorporate advanced technology for speed and efficiency. Today, machines like air jet looms, water jet looms, and rapier looms are popular in large-scale production, offering faster speeds and higher productivity.

| Traditional Hand Looms | These are manually operated machines where the shuttle is passed through the warp threads. While slow, hand looms are still used in small-scale, artisan fabric production. |

| Modern Weaving Machines | Automated machines such as air jet, water jet, and rapier looms have revolutionized textile production. These machines offer higher speeds, greater precision, and can handle complex fabric designs. |

The shuttle loom is one of the oldest types of weaving machines, still widely used today. It uses a shuttle—a small device that carries the weft thread—back and forth across the warp threads to create the fabric.

How it Works: The shuttle, which contains a bobbin of weft yarn, moves from one side of the loom to the other, inserting the yarn through the shed created by the warp threads.

Best Suited For: Shuttle looms are ideal for heavy, dense fabrics like denim, canvas, and tweed. They are also well-suited for creating fabrics with tightly locked edges (selvedges).

Pros:

Simple mechanical design

Produces durable fabrics with high-quality edges

Cons:

Slow speed (200-300 picks per minute)

Noisy operation

Requires manual intervention

Air jet looms are highly efficient machines that use compressed air to propel the weft thread through the warp threads. These looms are known for their speed and are ideal for high-volume production.

How it Works: Air jet looms use nozzles to shoot a jet of air, which carries the weft thread across the loom, creating fabric at much higher speeds than traditional shuttle looms.

Best Suited For: Light-to-medium weight fabrics such as cotton and polyester blends. These looms are commonly used in industries that require mass production of fabrics like bed sheets, clothing, and industrial textiles.

Pros:

High-speed operation (up to 1500 picks per minute)

Suitable for mass production

Low labor costs due to automation

Cons:

High energy consumption for compressed air systems

Less suitable for delicate or textured yarns

Water jet looms are another type of shuttleless loom that uses high-pressure water jets to carry the weft thread through the warp threads. They are commonly used for synthetic fiber fabrics.

How it Works: A jet of water is used to push the weft thread across the warp threads. This technology is energy-efficient compared to air jet looms.

Best Suited For: Synthetic fibers such as polyester, nylon, and acetate. Water jet looms are typically used to produce fabrics for technical applications like upholstery and industrial materials.

Pros:

High-speed operation (up to 1200 picks per minute)

Energy-efficient compared to air jet looms

Gentle on the yarn, reducing breakage

Cons:

Cannot be used for natural fibers like cotton or wool

Requires water filtration and recycling systems to manage the water used

Rapier looms use metal rapiers (thin rods or bands) to carry the weft thread across the loom. These machines are known for their flexibility and ability to produce a wide variety of fabric types.

How it Works: The weft thread is picked up by one rapier and carried to the center of the loom, where it is passed to another rapier that completes the insertion.

Best Suited For: A wide range of fabrics, from delicate silk and cotton to heavier upholstery fabrics like corduroy.

Pros:

Suitable for a wide variety of fabrics and yarn types

Produces high-quality, complex weaves

Relatively fast compared to shuttle looms

Cons:

Slower than air jet looms (typically 700-800 picks per minute)

Requires more maintenance due to mechanical complexity

The type of fabric you plan to produce plays a critical role in selecting the right weaving machine. For example, delicate fabrics like silk or fine cotton are better suited to rapier looms, while heavier fabrics like denim or canvas may require a shuttle loom for durability.

Larger factories often require high-speed looms like air jet or water jet looms to meet mass production demands. Smaller studios or businesses focusing on specialty fabrics may find shuttle or rapier looms to be more suitable due to their lower initial investment costs.

Quality and versatility are key factors when choosing a machine. If your business needs to produce a variety of fabrics with different designs and textures, a rapier loom offers the flexibility required for intricate patterns. For uniform fabric production at high speed, an air jet loom may be the best option.

Modern weaving machines have integrated automation and smart technology, including sensors and Internet of Things (IoT) systems. These advancements help optimize production by monitoring machine performance, predicting maintenance needs, and ensuring consistent fabric quality.

The integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems has revolutionized the design and manufacturing processes. These technologies allow for precise pattern creation and seamless integration with the loom, enabling manufacturers to produce high-quality, intricate designs.

Tip: If your business produces complex patterns or requires fast design modifications, integrating CAD/CAM systems with your looms can significantly streamline the production process.

Regular maintenance is essential for ensuring the longevity and optimal performance of weaving machines. This includes routine checks for mechanical parts, cleaning, and timely repairs.

Well-trained operators are crucial for the efficient and safe operation of weaving machines. Providing regular training ensures that operators can troubleshoot issues, make necessary adjustments, and maintain high-quality production standards.

Selecting the right weaving machine is crucial for textile manufacturers. The decision depends on factors such as fabric type, production scale, and quality. As technology advances, modern machines become faster and more efficient, enabling the production of diverse fabrics. Understanding weaving machines' capabilities helps businesses make informed choices that ensure quality and efficiency.

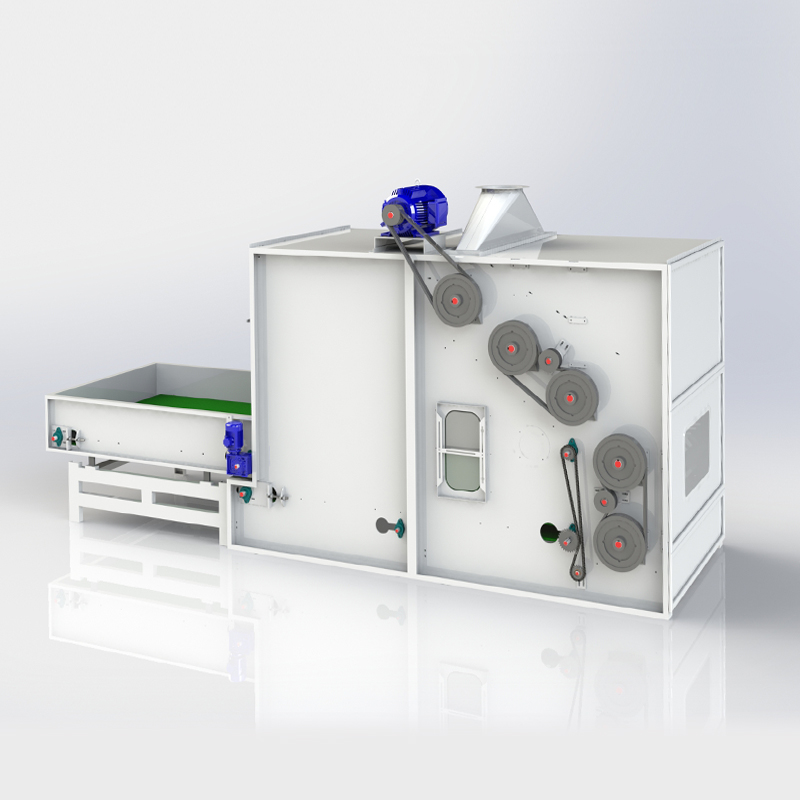

For companies like Weicheng, offering high-quality machines like the Mix Bale Opener, they provide excellent value by improving production speed and fabric quality, making them an ideal choice for businesses looking to enhance their manufacturing processes.

A: A woven fabrics machine, also known as a loom, is used to interlace warp and weft threads to create woven fabric. It plays a crucial role in fabric production.

A: A woven fabrics machine holds warp threads under tension while inserting weft threads across them. This creates fabric in various types, such as cotton, silk, or synthetic fibers.

A: Selecting the right woven fabrics machine ensures efficient production, fabric quality, and compatibility with the desired material, which can affect the final product’s durability and texture.

A: There are several types, including shuttle looms, air jet looms, and rapier looms. Each type offers different speeds, capabilities, and fabric suitability.

A: Consider fabric type, production scale, and desired quality. The right machine will enhance efficiency, reduce costs, and produce high-quality woven fabrics.