Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

Choosing the right fabric can be a game-changer for your project. Woven and nonwoven fabrics each have unique benefits. So, which one is better?

In this article, we’ll break down the differences between woven and nonwoven fabrics. You'll learn about their properties, advantages, and where each one shines.

Woven fabrics are constructed by weaving two sets of threads: the warp (vertical) and the weft (horizontal). This interlacing creates a grid-like structure that offers strength and durability. Woven fabrics are commonly made from materials like cotton, polyester, nylon, and wool.

Durability and Tensile Strength: Woven fabrics are known for their superior strength, which makes them ideal for applications requiring load-bearing capabilities, such as safety harnesses, automotive parts, and heavy-duty upholstery.

Customization: Woven fabrics can be tailored to specific requirements, such as varying thread counts, weaving patterns, and material blends, providing a wide range of options for various uses.

High Performance in Industrial Applications: Due to their inherent strength, woven fabrics are used in a variety of industries, including aerospace, automotive, and construction, where high-performance materials are critical.

Cost Considerations: Woven fabrics generally come at a higher price point due to the intricate manufacturing process.

Limited Permeability: Woven fabrics are not ideal for applications requiring high water permeability, such as drainage systems, because their tightly woven structure limits water flow.

Nonwoven fabrics are made by bonding fibers together using various methods, such as heat bonding, chemical bonding, or needle-punching. Unlike woven fabrics, they do not require interlacing threads, resulting in a more flexible and lightweight material.

Cost-Effective Production: Nonwoven fabrics are less expensive to produce and can be manufactured more quickly than woven fabrics, making them an economical option for disposable products.

Softness and Flexibility: These fabrics are softer and more pliable, making them ideal for applications such as medical gowns, diapers, and sanitary napkins.

Superior Liquid Resistance and Specialized Treatments: Nonwoven fabrics can be engineered to enhance properties like liquid resistance, bacterial protection, and thermal insulation, making them suitable for use in medical, filtration, and protective clothing applications.

Lower Durability: Nonwoven fabrics generally lack the long-term durability of woven fabrics, particularly in applications that require heavy-duty or load-bearing materials.

Limited Structural Reinforcement: Since nonwoven fabrics are not woven, they don't provide the same level of structural support and reinforcement as woven fabrics, making them less suitable for applications like soil stabilization.

Woven Fabrics: Due to the interlaced nature of their fibers, woven fabrics are stronger and more durable, making them suitable for heavy-duty applications like road construction and safety gear.

Nonwoven Fabrics: While nonwoven fabrics are more flexible and versatile, they are generally weaker and not as durable as woven fabrics for structural reinforcement.

Woven Fabrics: Woven fabrics offer low permeability, making them less suitable for water filtration or drainage applications. They are best used in applications where water retention or barrier properties are needed.

Nonwoven Fabrics: Nonwoven fabrics excel at high permeability, making them ideal for filtration and drainage systems, such as in wastewater treatment and landscaping.

Woven Fabrics: Typically more expensive and time-consuming to produce due to the complex weaving process. However, the investment may be worthwhile for applications requiring high strength and durability.

Nonwoven Fabrics: Less costly and faster to produce, nonwoven fabrics are an attractive option for disposable or single-use products, such as face masks and diapers.

| Feature | Woven Fabrics | Nonwoven Fabrics |

|---|---|---|

| Manufacturing Process | Interlacing threads (warp and weft) | Bonding fibers using heat, chemicals, or mechanical methods |

| Strength & Durability | High strength, durable, ideal for load-bearing | Generally weaker, flexible, suited for temporary use |

| Permeability | Low permeability, not ideal for drainage | High permeability, ideal for filtration and drainage |

| Cost | More expensive due to complex manufacturing | More cost-effective and faster to produce |

| Common Uses | Aerospace, automotive, construction, clothing | Medical products, filtration systems, disposable packaging |

| Customization | Highly customizable (thread count, weaving patterns) | Limited customization, but versatile in texture |

| Ideal for | Long-term, heavy-duty applications | Temporary, disposable, and medical uses |

| Examples of Products | Safety harnesses, upholstery, geotextiles | Face masks, diapers, geotextiles for landscaping |

Woven fabrics are ideal for aerospace, automotive, and construction industries, where strength and durability are paramount. Examples include safety harnesses, automotive upholstery, and reinforcement materials for construction.

Woven fabrics are commonly used in clothing (e.g., denim, shirts, trousers) and upholstery materials due to their durability and wide range of available textures.

Woven fabrics are widely used in soil stabilization, erosion control, and road construction, where they provide reinforcement and load distribution.

In the medical industry, woven fabrics are used in PPE (personal protective equipment), surgical drapes, and bandages, providing strength and barrier protection against contaminants.

Nonwoven fabrics are a go-to material for single-use items like masks, gowns, diapers, and sanitary napkins due to their flexibility, softness, and cost-effectiveness.

Nonwoven fabrics are commonly used in air and liquid filtration systems across various industries, providing excellent permeability for moisture and particle filtration.

In geotextiles, nonwoven fabrics play a crucial role in erosion control, drainage, and soil separation. Their high permeability and cost-effectiveness make them ideal for applications like French drains and underdrain systems.

Nonwoven fabrics are used for lightweight packaging materials, disposable food containers, and other one-time-use products, providing both strength and flexibility.

For Durability and Structural Support: Woven fabrics are the clear winner. They are ideal for heavy-duty applications where strength is required, such as in construction, automotive, and industrial uses.

For Drainage, Filtration, or Disposable Items: Nonwoven fabrics excel. Their high permeability makes them suitable for applications like medical products, filtration systems, and disposable products.

Construction and Geotextiles: For soil stabilization and erosion control, woven fabrics are recommended. Nonwoven fabrics work better for drainage-related tasks.

Medical and Hygiene: For single-use medical products, nonwoven fabrics are typically the best choice due to their fast production and softness.

Textiles and Upholstery: Woven fabrics are ideal for garments and furniture, offering durability and customization.

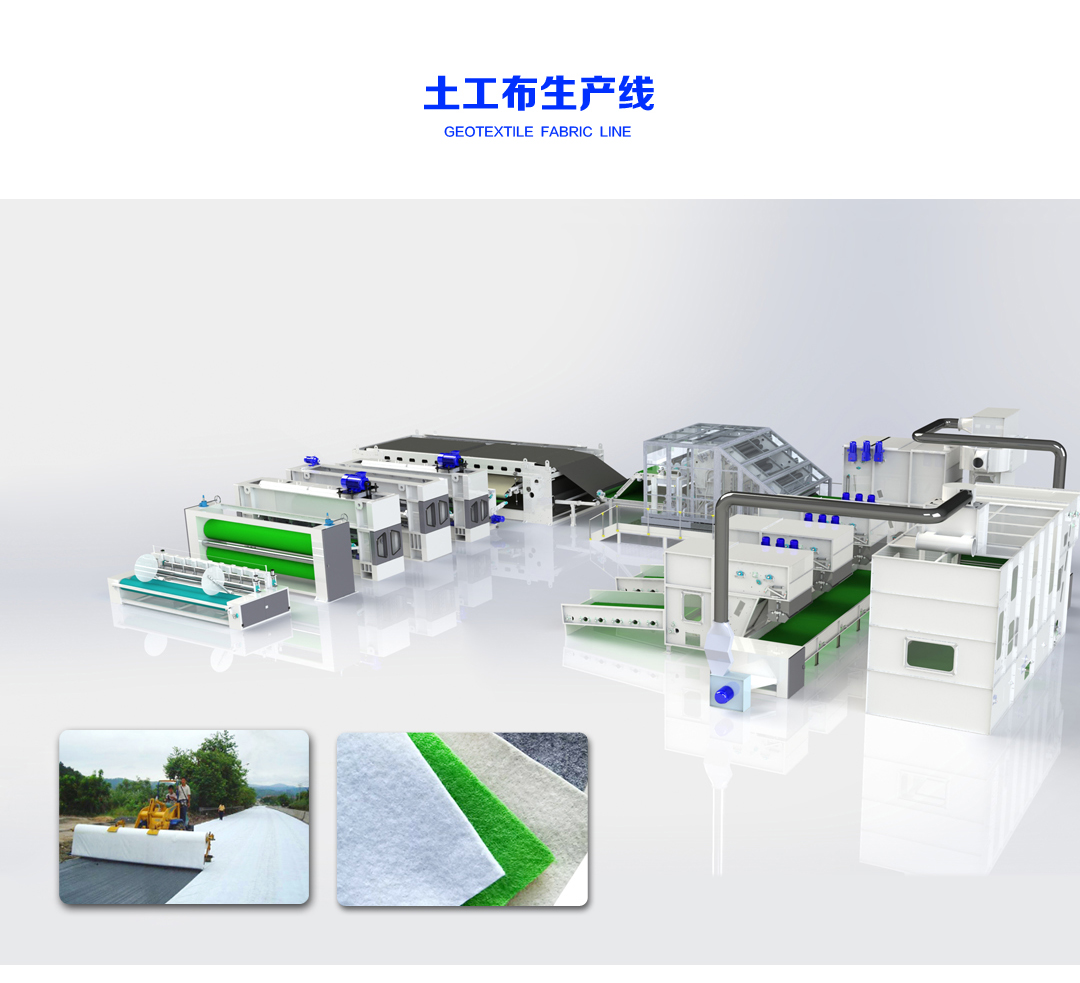

Woven fabrics are best for applications that require strength, durability, and load-bearing capacity, such as in aerospace, automotive, and construction. Nonwoven fabrics excel in flexibility, permeability, and cost-effectiveness, making them ideal for medical products, filtration, and disposable packaging. When choosing between the two, consider your project's specific needs. If durability is key, go for woven fabrics; if flexibility and fast production are needed, nonwoven is the way to go. For tailored solutions, Weicheng offers high-quality products that meet diverse industry requirements. Their advanced nonwoven machine production lines deliver excellent performance and value.

A: Woven fabrics are made by interlacing threads, offering strength and durability. Nonwoven fabrics are bonded through heat, chemicals, or mechanical methods, making them more flexible and cost-effective.

A: Woven fabrics are generally stronger and more durable due to their interlaced structure, making them ideal for heavy-duty applications. Nonwoven fabrics, while flexible, are typically weaker for structural reinforcement.

A: Nonwoven fabrics are cost-effective, lightweight, and flexible. They are commonly used in medical products, filtration systems, and disposable packaging due to their quick manufacturing process.

A: While nonwoven fabrics are great for temporary and disposable uses, they may not offer the same long-term durability as woven fabrics, especially for heavy-duty applications.

A: Nonwoven fabrics are ideal for medical applications like masks, gowns, and surgical drapes due to their flexibility, softness, and liquid resistance.

A: Yes, woven fabrics tend to be more expensive due to the complex manufacturing process and higher material costs, while nonwoven fabrics are quicker and more cost-effective to produce.

A: Yes, nonwoven fabrics are used in construction for erosion control, drainage systems, and soil separation, offering good permeability and cost-effectiveness.