Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

The textile industry is vast and essential, shaping everyday life with its products. But have you ever wondered how fibers turn into fabric? It’s all thanks to specialized textile industry machines.

In this article, we’ll explore the key machines in the textile industry, from fiber production to the final product. You’ll learn how these machines work and why they’re crucial for efficient, high-quality textile production.

The textile industry relies heavily on machinery to convert raw materials into finished goods. Each machine in the production line plays a crucial role in shaping the quality and efficiency of textile production. Let's take a look at the different types of textile industry machines used across various stages of production.

The production of textiles starts with raw fibers, which are processed into threads or yarn. This section covers the key machines used in converting raw materials into yarn.

Woolen mill machines are designed to process wool into yarn, making them essential in the production of wool-based fabrics. Wool, known for its thermal properties, is used in a wide variety of textile products. Woolen mill machines help turn raw wool into finely spun yarn that is further processed into fabric.

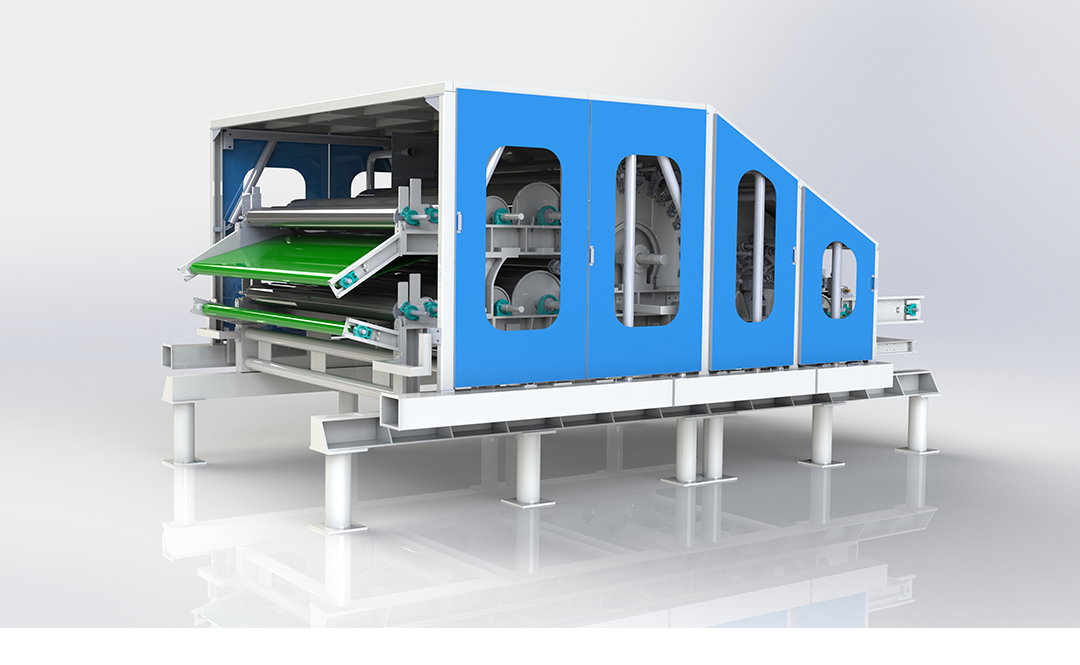

Carding machines prepare raw fibers, like wool or cotton, by opening and cleaning the fibers before they are spun into yarn. These machines are critical in ensuring the smoothness and consistency of the fibers, removing dirt, and aligning the fibers for spinning.

Spinning machines are the heart of yarn production. They twist fibers into yarn, which can then be used in fabric production. There are two main types of spinning machines: ring spinning and rotor spinning. Ring spinning is widely used for finer yarns, while rotor spinning is faster and more cost-effective for thicker yarns.

Yarn gassing machines are used to remove excess fuzz and improve the color intensity of yarn. These machines work by heating the yarn with a controlled flame, which helps smooth out the yarn’s surface and enhances its overall appearance.

Once yarn and threads are produced, they are used to create fabric. The following machines are responsible for weaving, knitting, and tufting yarns into fabric.

Weaving machines, also known as looms, are used to interlace yarns together to form fabric. There are several types of weaving machines, including power looms, rapier looms, and air-jet looms. Power looms are commonly used for mass production, while rapier looms are more flexible and ideal for complex fabric patterns. Air-jet looms, known for their speed and efficiency, use air to propel the yarn through the loom, making them suitable for high-speed production.

Knitting machines are used to produce knitted fabrics from yarn. These machines create a series of interlocking loops of yarn to form the fabric. There are two main types of knitting: circular knitting and flat knitting. Circular knitting machines produce tubular fabric, commonly used in hosiery and seamless garments, while flat knitting machines are used for producing items like sweaters.

Tufting machines are used to insert yarn into a fabric base, creating textiles like carpets and mats. These machines are particularly useful for manufacturing fabrics that require a raised, textured surface.

Crochet machines are designed to create crocheted fabrics, often used in fashion and home textiles. These machines interlace yarns in a unique pattern to form decorative fabrics, making them essential in the production of intricate textiles.

After fabrics are created, they often require dyeing and finishing to achieve the desired appearance, texture, and durability. This section explores the machines responsible for dyeing and finishing textiles.

Bleaching and dyeing are essential processes in the textile industry. Bleaching machines are used to remove natural colors from fibers, while dyeing machines apply color to fabrics, ensuring consistent and uniform shades. These machines help achieve vibrant and lasting colors in textiles.

Tip: Consider using eco-friendly dyeing machines that minimize water and energy consumption. These machines are increasingly important for businesses seeking to improve sustainability.

Jet dyeing machines use high-pressure jets to circulate dye liquor over fabrics, ensuring uniform color distribution. These machines are particularly useful for dyeing delicate fabrics and achieving consistent results in high-speed production environments.

Stenter machines are used to stretch and dry fabrics to the desired width, ensuring they meet quality standards. These machines are essential in finishing processes, as they help control fabric shrinkage and improve texture.

The final stage of textile production involves stitching and assembling fabrics into finished products such as garments. These machines are crucial for the creation of ready-to-wear textiles.

Industrial sewing machines are heavy-duty machines designed for large-scale garment production. Unlike domestic sewing machines, these machines can handle high volumes and are built to last. They are used for stitching fabric pieces together to create garments.

Quilting machines are used to stitch multiple layers of fabric together to create quilted textiles. These machines are commonly used in the production of bedding, outerwear, and insulated fabrics.

Monogramming machines are used to embroider initials or other designs onto fabrics. These machines are commonly used in personalizing towels, shirts, and other textile products.

Quality control is a crucial aspect of textile production, ensuring that the final product meets industry standards for durability and performance.

Tensile testing machines are used to measure the strength and elasticity of textiles. These machines are essential in ensuring that fabrics can withstand the stresses and strains they will face during use.

These machines test how well a fabric retains its color when exposed to various conditions like washing, light exposure, and rubbing. They are crucial for ensuring that dyed textiles maintain their appearance over time.

| Machine Type | Function |

|---|---|

| Textile Industry Machines | Transform raw fibers into finished textile products through various processes like spinning, weaving, dyeing, and quality control. |

| Carding Machines | Open and clean raw fibers, preparing them for spinning into yarn. |

| Spinning Machines | Twist fibers into yarn, which is essential for fabric production. |

| Weaving Looms | Weave yarn into fabric through various types of looms, including power, rapier, and air-jet looms. |

| Dyeing Machines | Apply color to fabric, ensuring uniformity and precision. |

| Sewing Machines | Stitch fabric pieces together to create garments or other textile products. |

| Tufting Machines | Insert yarn into fabric bases to create textiles like carpets and mats. |

| Knitting Machines | Create knitted fabrics, essential for items like sweaters and hosiery. |

| Quality Control Machines | Ensure fabric strength, elasticity, and color retention to meet industry standards. |

Modern technology has revolutionized the textile industry, allowing for smarter, more efficient production processes. Automation and digital innovations are helping businesses reduce waste, improve efficiency, and enhance product quality.

These advanced machines use sensors and real-time monitoring to optimize production, reduce material waste, and improve fabric quality. Automation helps manufacturers monitor every aspect of the process, ensuring greater consistency and efficiency.

Digital printing machines offer a more sustainable and efficient alternative to traditional screen printing. These machines use digital technology to apply designs directly onto fabric, reducing water and ink waste while allowing for high-resolution prints on demand.

The growing demand for eco-friendly production methods has led to the development of sustainable textile machinery. These machines focus on reducing energy consumption, conserving water, and using environmentally friendly materials in the production process.

The textile industry relies on various machines, each essential for converting raw fibers into finished products. These machines support every stage, from fiber production to dyeing, weaving, and quality control. Understanding their roles helps manufacturers make informed decisions on equipment investments, improving efficiency and product quality.

By integrating the right machines, businesses can reduce waste, enhance operations, and meet the increasing demand for sustainable textiles. Companies like Weicheng offer advanced machinery, such as the Industrial Carding Machine, which boosts efficiency and product quality.

A: Textile industry machines are used to transform raw fibers into finished textile products. They perform various tasks like spinning, weaving, dyeing, and quality control, making the production process more efficient and consistent.

A: These machines automate critical processes like carding, spinning, and weaving, speeding up production, reducing errors, and ensuring high-quality textile products, which improves overall efficiency.

A: Common textile industry machines include carding machines, spinning machines, weaving looms, dyeing machines, and sewing machines, each serving a specific role in fabric production.

A: Textile industry machines help reduce waste, improve energy efficiency, and optimize material use, contributing to more sustainable and eco-friendly textile production.

A: The cost of textile industry machines varies depending on the type and features. Machines like carding and spinning equipment may range from several thousand to hundreds of thousands of dollars.

A: Yes, textile industry machines ensure precision in fabric production, improving quality by consistently controlling parameters like tension, color, and texture throughout the process.